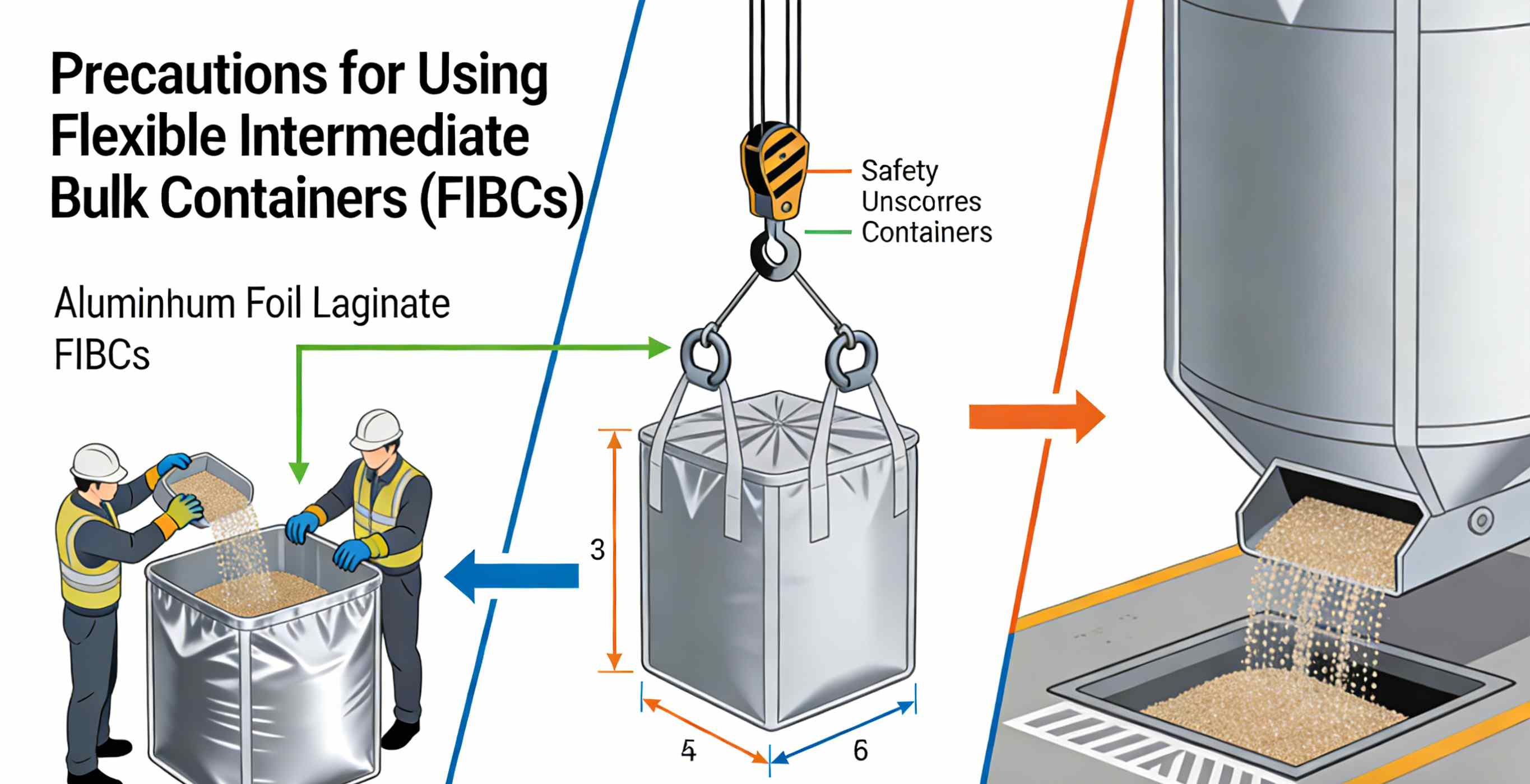

Proper operational procedures during use directly affect the quality and safety of the bags. Key precautions are as follows:

1. Loading Specifications:Avoid impacting the bag body with the material during loading, especially sharp or granular substances. Handle gently to prevent punctures.Control the feeding speed and ensure the fill level does not exceed 80%-90% of the rated load capacity. Leave sufficient space to prevent spillage during lifting.

2. Lifting Operations:Before lifting, ensure all lifting straps/loops bear weight evenly. Never lift using only a single strap.Use dedicated lifting equipment and engage all lifting straps/loops.Prohibit personnel from staying or passing underneath the suspended FIBC to avoid injury from potential falls.Move at a moderate speed to prevent the FIBC from colliding with or scraping against objects.

3. Unloading Requirements:Place the FIBC down steadily during unloading to avoid sharp impacts.Choose the appropriate unloading method based on the bag's design. Close any sealing openings promptly after unloading to prevent leakage of residual material.When unloading flammable or explosive materials, operate in a well-ventilated area free of ignition sources.

4. Special Scenario Considerations: In humid environments or when transporting hygroscopic powders, prioritize the use of a Dust-Tight Aluminum Foil Laminate FIBC to ensure an absolute moisture and oxygen barrier. In high-temperature settings, confirm the high-temperature resistance of the material. During transport, stack bags reasonably. To improve warehouse safety and minimize leaning, consider utilizing a Heavy Duty Form Stable Baffle FIBC, which maintains a square shape better than standard bags. Stacking height should not exceed three times the FIBC's own height.

| Operational Scenario |

Potential Risk |

Recommended Solution |

| Outdoor / Long-term Storage |

Fabric degradation due to UV exposure |

Heavy Duty UV Resistant FIBC

(Ensures structural integrity >144h UV testing) |

| Fine Powder / Chemicals |

Moisture ingress & caking |

Dust-Tight Aluminum Foil Laminate FIBC

(Provides near-zero WVTR barrier) |

| High-Density Export |

Stack leaning & Space wastage |

Heavy Duty Form Stable Baffle FIBC

(Increases container payload by 15-20%) |

After Use: Proper Storage to Extend Service Life

For reusable FIBCs, proper storage after use can effectively extend their service life:

1. Cleaning Process: After unloading, promptly clean out any residual material from the bag. This is especially important for corrosive or adhesive materials to prevent bag deterioration or bacterial growth.

2. Storage Environment: Store cleaned and dried FIBCs in a dry, well-ventilated, indoor area protected from light. Avoid direct sunlight, damp conditions that could cause mold, or exposure to high heat. Never store FIBCs together with sharp objects or corrosive substances to prevent damage.

3. Storage Method: Bags can be folded neatly for storage, avoiding excessive compression. Alternatively, hanging storage is recommended to minimize wear and tear. Clearly categorize and label FIBCs by function and load capacity for easy identification and future use.