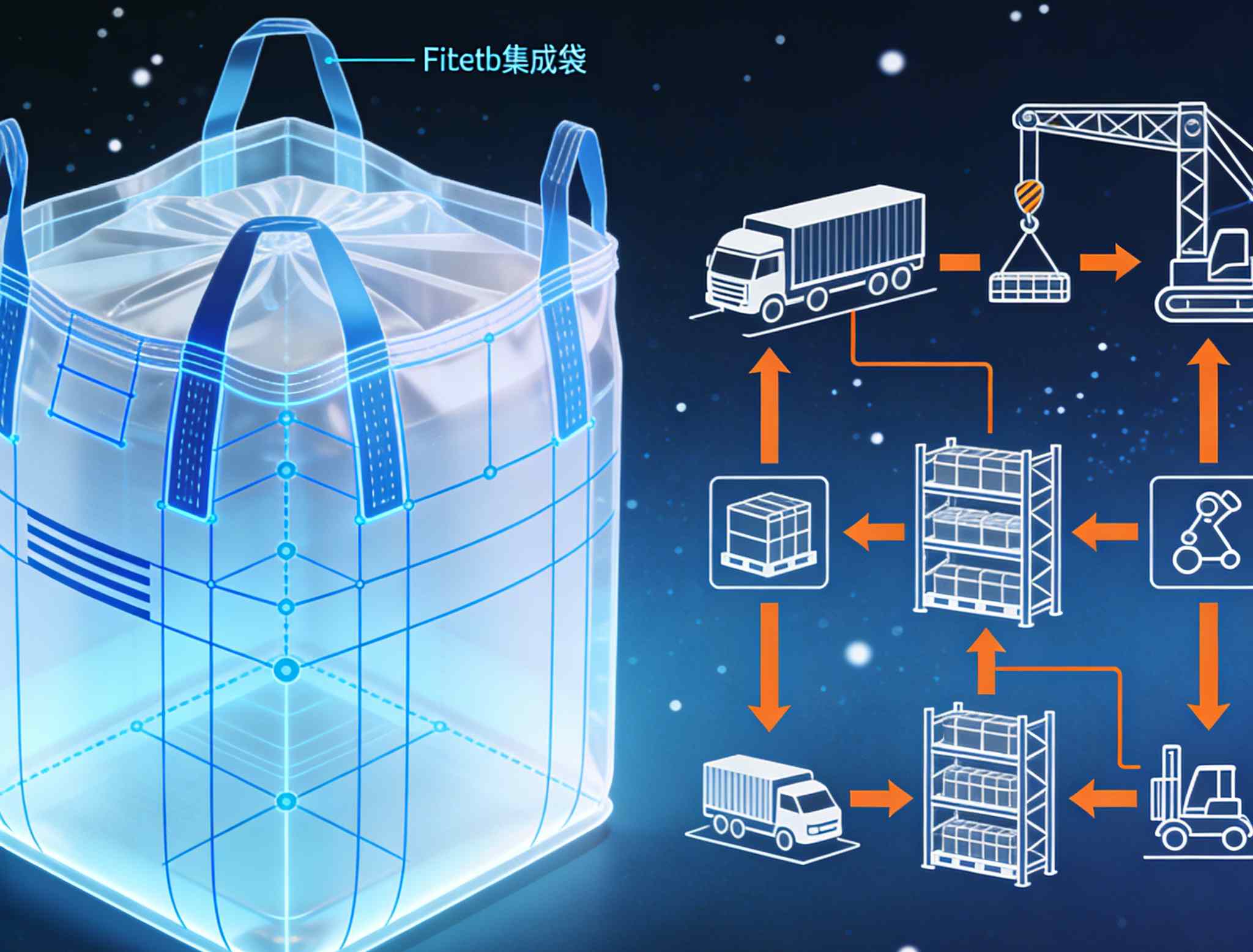

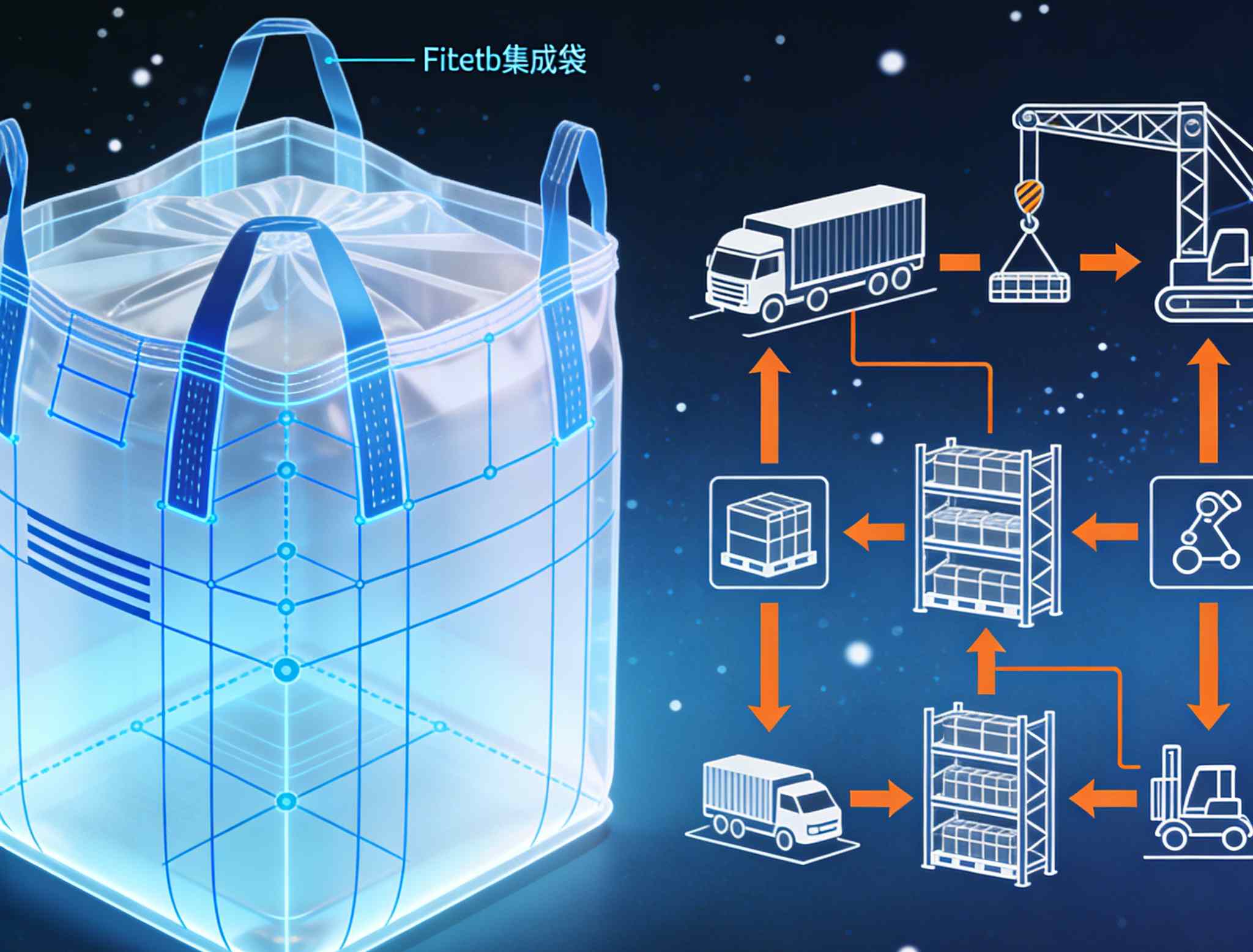

Eliminating Invisible Loss: A Strategic Guide to FIBC Selection and Logistics Optimization

In the complex supply chains of the chemical, construction, and food processing industries, procurement managers often grapple with a hidden "cost trap." What appears to be a nominal saving on unit packaging costs often manifests later as significant financial hemorrhage due to transit damage, moisture contamination, or inefficient container utilization.

A Flexible Intermediate Bulk Container (FIBC) is not merely a bag; it is a precision logistics instrument. To navigate this, we must deconstruct FIBC selection through three critical lenses: Material Physics, Spatial Engineering, and Total Cost of Ownership (TCO).

Material Physics: Beyond Simple Containment

The fundamental structure of most bulk bags is woven polypropylene (PP) tape. A critical oversight in procurement is ignoring the microscopic reality of this weave: it contains physical gaps. While standard fabric suits coarse aggregates, it fails with ultra-fine powders or hygroscopic chemicals.

For high-sensitivity scenarios, the Aluminum Foil Laminate FIBC is the superior industrial-grade solution. Unlike standard coatings, the multi-layer aluminum structure provides an absolute barrier.

| Performance Metric |

Standard PP Coated Bag |

Aluminum Foil Laminate FIBC |

| Water Vapor Transmission (WVTR) |

~2.0 - 5.0 g/m²/24h |

< 0.05 g/m²/24h |

| Oxygen Transmission (OTR) |

High (Permeable) |

Negligible |

| Static Protection |

Requires additives |

Inherent Shielding |

Spatial Engineering: Gaining 20% More Volume

Freight costs are determined by volume as much as weight. Traditional bags tend to bulge into a "pear shape" when filled, creating dead space in shipping containers and reducing stability.

If your logistics involve high-volume export, the Form Stable Baffle FIBC is a critical efficiency tool. Internal baffles maintain the bag's cubic shape, preventing deformation.

Key Efficiency Data:

- Space Utilization: Standard bags waste 15-20% of container space; Baffle bags achieve over 95% utilization.

- Stability: The rectangular footprint allows for safer, higher stacking in warehouses, reducing footprint costs.

Matching Load to Scenario: Precision Specification

Over-specification is as wasteful as under-specification. Not every load requires heavy-duty fabric. For industries handling low-density materials like insulation, dried biomass, or plastic scraps, standard bags add unnecessary weight and cost.

The Lightweight PP Woven Bulk Bag is engineered specifically for these scenarios. It optimizes the tensile strength-to-weight ratio, providing a cost-effective solution without compromising safety for lighter loads. Conversely, for high-density mining materials, a Safety Factor (SF) of 6:1 is mandatory for reusable bags, whereas 5:1 suffices for single trips.

The "Three Lines of Defense" in Quality Control

Regardless of the bag type, quality control is the non-negotiable baseline. The market is flooded with products lacking traceability. To ensure operational safety, verify three technical parameters:

1. UV Resistance: For outdoor storage, verify that the fabric retains 50% of its tensile strength after 144 hours of accelerated weathering testing.

2. Lifting Loop Integrity: Check for reinforced stitching at connection points. This is the highest stress area during handling.

3. Fabric Uniformity: Inspect the bag against a light source. Uneven transparency indicates inconsistent weaving or impurity in the PP mix, which are precursors to structural failure.

Procuring FIBCs is a technical decision based on material properties and logistics environments. By precisely matching specifications to the application—whether prioritizing moisture barriers, cubic efficiency, or weight optimization—businesses secure not just a container, but a streamlined supply chain.